Compostable vs Recyclable: 6 Key Material Differences

Share

Decoding Disposal: Compostable vs. Recyclable

Confused about compostable vs. recyclable? This listicle clarifies six key differences to help you make eco-conscious disposal choices. Learn how these materials decompose, their environmental impact, relevant certifications, the science behind them, how they're processed, and the economics involved. Understanding these distinctions empowers you to minimize your footprint and contribute to a healthier planet. Let's explore these differences and become disposal experts.

1. Material Decomposition Process

Understanding the difference between "compostable" and "recyclable" is crucial for anyone striving for a more sustainable lifestyle. This distinction lies in how these materials break down and return to the earth or back into production cycles. Compostable materials undergo biodegradation, a natural process driven by microorganisms that break down organic matter into nutrient-rich soil. Recyclable materials, on the other hand, are processed mechanically or chemically to recover raw materials without fundamentally altering their properties, enabling their reuse in new products. This core difference impacts how we dispose of items and their ultimate environmental impact.

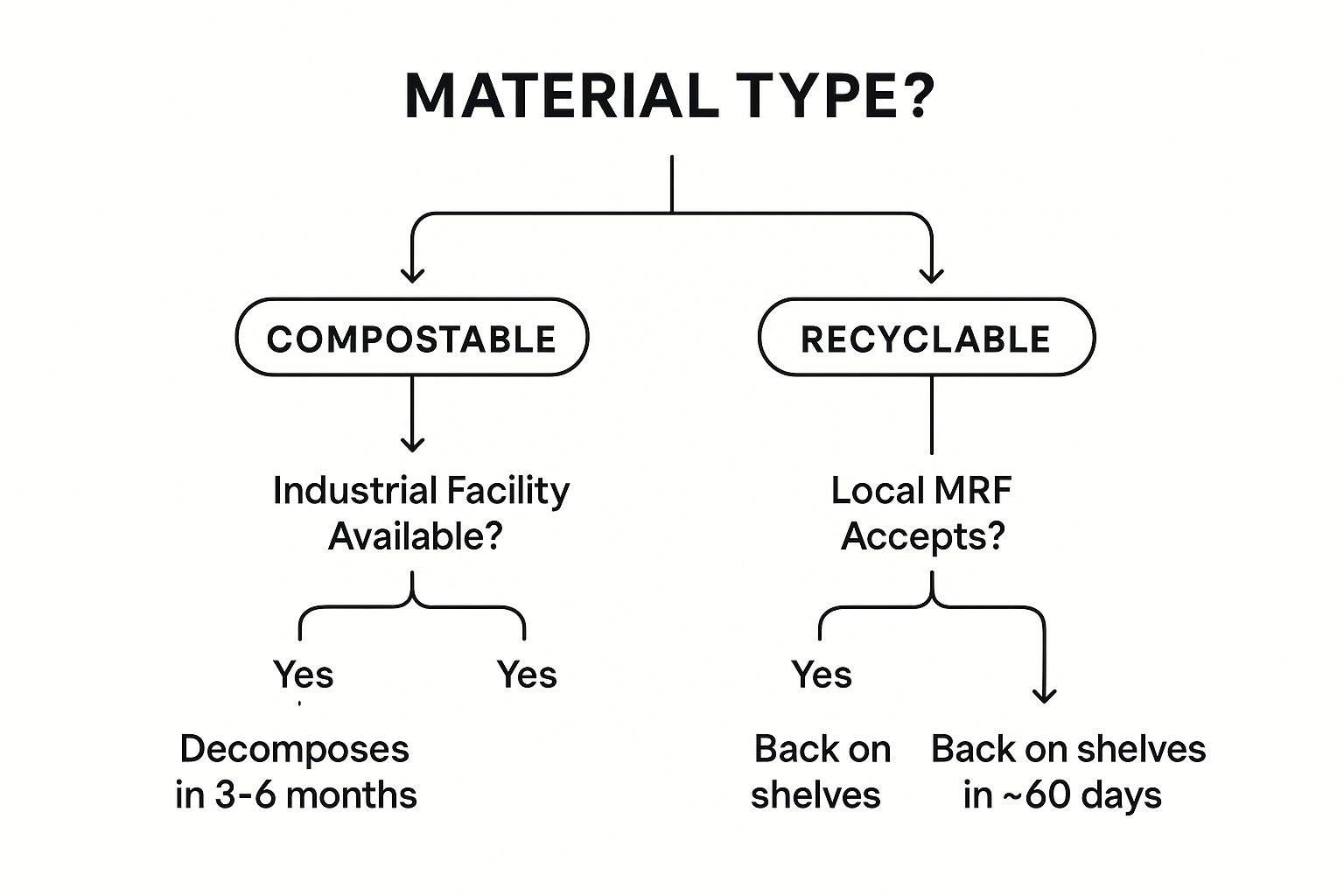

The infographic above presents a decision tree to help you determine whether an item is compostable or recyclable. It starts by asking if the material is organic. If yes, it proceeds to inquire whether the item is suitable for home composting or requires an industrial composting facility. If the material is not organic, the decision tree directs you to consider whether it's accepted in your local recycling program. This visualization clarifies the distinct pathways for compostable and recyclable materials.

The decomposition timeline also varies significantly. Compostable materials typically break down within 3-6 months in proper composting conditions (industrial or home composting, depending on the material). Recyclable materials, however, can be reprocessed and back on shelves in as little as 60 days. This speed and the preservation of material properties make recycling an efficient process for certain materials. For example, aluminum cans can be recycled indefinitely without any loss in quality, while PLA (polylactic acid) plastic cups, often used for cold beverages, require industrial composting facilities to break down.

Composting offers the benefit of creating nutrient-rich soil amendments, vital for healthy gardens and reducing our reliance on synthetic fertilizers. Recycling conserves raw materials, reducing the environmental burden of extraction and manufacturing. Both methods significantly reduce landfill waste, a crucial step towards sustainable waste management. However, both processes have limitations. Compostable materials, despite being "biodegradable," often require industrial facilities due to the high temperatures needed for proper decomposition, making home composting unsuitable for certain items. Many recyclable materials, especially plastics, degrade in quality with each cycle (a process called downcycling), limiting their lifespan in the recycling loop. Furthermore, both composting and recycling require specific environmental conditions to function effectively.

Here are some actionable tips for implementing these waste reduction strategies:

- Check your local regulations: Research whether your local waste management system accepts specific compostable materials and what type of composting they utilize (industrial or home).

- Understand “biodegradable” vs. "compostable": "Biodegradable" simply means a material will eventually break down. "Compostable" signifies it will break down into usable compost in a specific timeframe and under specific conditions.

- Clean your recyclables: Rinsing and cleaning recyclables, especially food containers, significantly improves the efficiency of recycling processes and reduces contamination.

This understanding of the material decomposition process empowers you to make informed decisions about your waste, minimizing your environmental impact and contributing to a more sustainable future. By considering whether an item is truly compostable in your specific context and diligently recycling appropriate materials, you actively participate in closing the loop on resource consumption and reducing our reliance on landfills.

2. Environmental Impact Analysis

Understanding the true sustainability of a product requires looking beyond just its disposal. A comprehensive Environmental Impact Analysis (EIA) provides a crucial lens for comparing compostable vs. recyclable materials by examining their complete lifecycle – from resource extraction and manufacturing to transportation, use, and ultimately, end-of-life processing. This cradle-to-grave assessment considers a wide range of environmental factors, including greenhouse gas emissions, water usage, soil health, and broader ecosystem effects. It allows us to make informed choices about the products we consume and support, moving beyond simple labels and marketing claims.

EIAs employ lifecycle assessment (LCA) methodology to quantify these impacts. This involves calculating the carbon footprint associated with production and disposal processes, assessing resource depletion for both compostable and recyclable options, evaluating land use requirements for different disposal systems (e.g., composting facilities vs. recycling plants), and determining the energy inputs needed for manufacturing and processing. This multifaceted approach helps reveal the hidden environmental costs often overlooked by simpler comparisons.

For instance, the EPA estimates that recycling 10 tons of aluminum saves a staggering 14,000 kWh of energy, highlighting the potential benefits of recycling. Studies have also shown that compostable packaging can reduce CO2 emissions by 30-70% compared to conventional plastics, demonstrating the potential of compostable materials to mitigate climate change. Organizations like the UK's WRAP conduct extensive research on comparative lifecycle impacts, providing valuable data for informed decision-making. These examples showcase the practical application of EIA and its power to reveal the true environmental trade-offs between different material choices.

Pros of considering EIA when comparing compostable vs. recyclable:

- Compostable materials often have lower end-of-life carbon footprints, returning nutrients to the soil.

- Recycling typically requires less energy than producing new materials from virgin resources.

- Both composting and recycling can reduce methane emissions from landfills, a potent greenhouse gas.

Cons to be aware of:

- Some compostable materials have higher manufacturing environmental impacts due to resource-intensive production processes.

- Recycling processes can involve chemical treatments and potentially contribute to water pollution.

- Transportation impacts exist for both compostable and recyclable systems, contributing to their overall environmental footprint.

Tips for Using Environmental Impact Analysis:

- Consider the full lifecycle impact: Don't focus solely on end-of-life disposal. The entire production and consumption chain matters.

- Look for third-party verified EIAs: Independent verification ensures greater credibility and transparency.

- Regional factors greatly affect comparative environmental benefits: Access to composting facilities, recycling infrastructure, and energy sources varies significantly, influencing the overall impact.

This item deserves a place on this list because for the eco-conscious consumer, understanding the full environmental picture is paramount. EIA provides the necessary tools to evaluate the complex interplay of factors that determine the true sustainability of compostable and recyclable materials, empowering informed choices that align with personal values and contribute to a healthier planet. The work of pioneers like William McDonough and Michael Braungart (authors of Cradle to Cradle) and the Ellen MacArthur Foundation's circular economy research have further popularized the importance of lifecycle thinking and its implications for sustainable material selection.

3. Certification Standards and Regulations

Navigating the world of compostable vs. recyclable materials can be confusing. Understanding the role of certification standards and regulations is crucial for making informed choices and supporting truly sustainable practices. These frameworks provide a consistent set of criteria for evaluating materials, ensuring they perform as claimed – whether that's breaking down in a compost environment or being successfully reprocessed into new materials – and fostering trust in the marketplace. This is essential for businesses and consumers alike when comparing compostable vs. recyclable options.

Several organizations have developed specific standards and certifications for both compostable and recyclable materials. Compostable certifications include ASTM D6400 (for plastics that compost in municipal or industrial facilities), EN 13432 (the European equivalent), and BPI (Biodegradable Products Institute) certification, which is widely recognized in North America. These certifications often involve time-based decomposition requirements, ensuring the material breaks down within a specific timeframe, and toxicity testing of compost residues to confirm the safety of the resulting compost for plants and the environment.

For recyclable materials, resin identification codes (those numbered symbols you see on plastic) help categorize different plastic types, while standards like ISO 14021 provide guidelines for environmental labels and declarations, including recyclability claims. Recycling standards also address material purity requirements for recycling streams, ensuring that contaminants don't disrupt the recycling process. As regulations around sustainable packaging evolve, businesses are increasingly seeking eco friendly takeout containers and other packaging solutions. For a deeper dive into sustainable options, Top Eco Friendly Takeout Containers for Your Business from MrTakeOutBags.com provides additional insights.

The presence of these certifications offers several advantages. They provide a consistent baseline for material performance claims, allowing consumers to compare “apples to apples.” This helps reduce greenwashing and false environmental claims, giving consumers more confidence in the products they purchase. Clear certification logos enable consumers to easily identify items that are genuinely compostable or recyclable.

However, there are also drawbacks. Multiple competing standards can create consumer confusion. For example, a product certified “compostable” might only be suitable for industrial composting facilities, not home composting. Furthermore, certification testing often doesn’t perfectly match real-world conditions. Finally, the expensive certification processes can be barriers for smaller producers, potentially limiting innovation and competition in the sustainable materials market.

Examples of these certifications in action include the BPI (Biodegradable Products Institute) certification for compostable products, frequently found on compostable food service ware, and the How2Recycle labeling system for recyclable materials, providing clear instructions on how to recycle different packaging components. European Bioplastics also offers a robust certification program.

When evaluating compostable vs. recyclable products, keep these tips in mind:

- Look for certification logos on packaging to verify claims. Don't just take the manufacturer's word for it.

- Understand the difference between "home compostable" and "industrial compostable" certifications. Not all compostable materials are created equal.

- Check local recycling guidelines, as they often differ from national standards. What's recyclable in one city might not be in another.

By understanding the landscape of certification standards and regulations, consumers and businesses can make informed decisions about compostable vs. recyclable materials and contribute to a more sustainable future. These certifications play a vital role in ensuring transparency and accountability in the increasingly complex world of eco-conscious products.

4. Materials Science Innovation

The age-old question of "compostable vs recyclable" is being challenged by exciting advancements in materials science. This field is revolutionizing how we think about end-of-life management for products by developing innovative materials that blur the lines between traditional composting and recycling. These innovations are crucial for a future where waste is minimized and resources are utilized more efficiently. This area of development deserves a spot on this list because it represents a potential paradigm shift in how we handle waste, moving beyond simply choosing between compostable vs recyclable and towards a more integrated and sustainable approach.

These cutting-edge scientific endeavors focus on creating new materials with improved end-of-life options. This includes research into:

- Plant-based polymers: These polymers can be both recycled and composted, offering greater flexibility in waste management. Imagine a food container that can be tossed in your backyard compost if you have one, or recycled if you don't.

- Additive technologies: Scientists are exploring how additives can enhance the biodegradation of traditionally non-compostable materials, expanding the range of items that can be composted.

- Smart materials: These innovative materials respond to environmental triggers like moisture or temperature changes, accelerating decomposition under specific conditions.

- Improved separation technologies: For complex multi-material products, researchers are developing advanced separation technologies to make recycling more efficient. This allows for better recovery of valuable materials from items that were previously difficult to recycle.

- Marine-degradable materials: Recognizing the impact of plastic pollution on our oceans, scientists are developing materials that break down safely in marine environments.

Examples of Materials Science Innovation in Action:

- Ecovative Design: This company utilizes mycelium (mushroom roots) to create compostable packaging materials, offering a sustainable alternative to Styrofoam and other petroleum-based packaging. Check them out at https://ecovativedesign.com/

- TIPA Compostable Packaging: TIPA develops compostable flexible packaging solutions for food and other products, aiming to replace conventional plastic films with fully compostable alternatives. Learn more at https://www.tipa-corp.com/

- Full Cycle Bioplastics: This company utilizes food waste as a feedstock to produce PHA (polyhydroxyalkanoate), a type of bioplastic that is both compostable and biodegradable.

Pros:

- Creates materials with improved end-of-life options, reducing landfill waste.

- Reduces our reliance on fossil-fuel based materials.

- Addresses the limitations of current disposal systems by providing more options for waste management.

Cons:

- New materials often carry a higher price tag than conventional alternatives.

- Existing waste infrastructure may not be equipped to handle these novel materials. Widespread adoption requires investment in new processing facilities and systems.

- Scaling production from laboratory research to commercial availability can be challenging and time-consuming.

Tips for Navigating the World of Innovative Materials:

- Evaluate the full lifecycle performance: Consider the environmental impact of a material from its production to its end-of-life.

- Check your local infrastructure: Ensure your local composting or recycling facilities can process the innovative materials you choose.

- Look for independent verification: Seek out products with independently verified performance claims to ensure they meet the advertised standards for compostability or recyclability.

These advancements in materials science hold immense promise for a more sustainable future. By understanding the potential of these innovations and making informed choices, consumers can contribute to a circular economy where waste is minimized and resources are valued. As you consider the "compostable vs recyclable" dilemma, remember that materials science is constantly evolving, offering exciting new solutions that go beyond this traditional dichotomy. The future of waste management is dynamic, and these innovations are leading the way.

5. Infrastructure and Processing Systems

A critical, yet often overlooked, aspect of the "compostable vs. recyclable" debate revolves around the infrastructure and processing systems required to manage these materials. This encompasses the entire journey of waste materials, from collection at the curb to their transformation into usable compost or recycled products. Understanding these systems is crucial for making informed choices about which disposal method is truly more sustainable in your area. These systems are comprised of municipal collection programs, specialized processing facilities, and the logistical networks that connect them. Without adequate infrastructure, even the most well-intentioned efforts to compost or recycle can be undermined.

Industrial composting facilities employ various methods like windrow composting (long piles turned regularly), in-vessel composting (enclosed systems), and aerated static pile composting (piles with forced aeration). Materials recovery facilities (MRFs) handle recyclables, utilizing a combination of automated sorting technologies (optical scanners, magnets) and manual labor to separate different materials. Collection systems can vary, with some municipalities adopting single-stream recycling (all recyclables in one bin) while others prefer source-separated collection (separate bins for different materials). Technologies for contamination detection and removal are also evolving, playing a key role in maximizing resource recovery.

This factor deserves a place on this list because choosing between compostable and recyclable products is meaningless if your local infrastructure can't handle them. For example, a compostable coffee cup offers little environmental benefit if it ends up in a landfill due to a lack of composting facilities. Conversely, recyclable materials may be downcycled or even landfilled if the local MRF lacks the capacity to process them effectively.

Pros:

- Economies of scale: Larger, centralized processing facilities can achieve higher efficiency for both composting and recycling.

- Advanced sorting technologies: Modern MRFs utilize sophisticated technologies to increase material recovery rates and minimize waste.

- Integrated systems: Some regions have developed integrated systems capable of processing multiple waste streams, optimizing resource utilization.

Cons:

- High capital costs: Establishing and maintaining the necessary infrastructure for composting and recycling requires significant investment.

- Regional disparities: Many regions lack adequate processing facilities, particularly for compostables, limiting the feasibility of these options.

- Contamination: Cross-contamination between compostable and recyclable streams reduces the effectiveness of both systems, potentially rendering materials unusable.

Examples of Successful Implementation:

- San Francisco's comprehensive composting program: The city's commitment to composting has achieved an impressive 80% diversion rate, demonstrating the potential of well-developed infrastructure.

- Germany's DSD (Duales System Deutschland): This system provides a model for nationwide recycling infrastructure, demonstrating the effectiveness of standardized collection and processing.

- Netherlands' Organic Waste Treatment facilities: The Netherlands has invested heavily in organic waste treatment, showcasing advanced composting technologies and infrastructure.

Tips for Making Informed Choices:

- Research local infrastructure: Before opting for compostable or recyclable products, investigate your local municipality's capabilities. Check their website or contact them directly to understand what materials are accepted and how they are processed.

- Support community initiatives: Advocate for improved local processing facilities and support organizations working to expand composting and recycling programs.

- Match material choice to infrastructure: Ensure your choices align with the available infrastructure. Opting for recyclable materials in an area with robust recycling but limited composting infrastructure makes more sense than choosing compostables destined for the landfill.

By understanding the complexities of infrastructure and processing systems, you can make more informed decisions about compostable vs. recyclable choices, contributing to a truly sustainable future. Supporting policies and initiatives that improve these systems is equally important, driving systemic change toward more efficient and effective waste management.

6. Economic Models and Market Dynamics

When choosing between compostable vs recyclable materials, the economic realities of each system play a crucial role in their feasibility and long-term success. This section explores the market forces, financial incentives, and business models that influence the adoption and viability of both compostable and recyclable solutions. Understanding these dynamics is critical for informed decision-making, whether you're a conscious consumer, a business owner, or a policymaker.

The economic landscape for both compostable and recyclable materials is complex and constantly evolving. It encompasses the entire lifecycle of a product, from raw material extraction and manufacturing to end-of-life management. Key factors include:

- Cost Structures: Production and processing costs differ significantly between compostable and recyclable materials. Compostable materials, often derived from renewable resources, can be more expensive to produce than conventional plastics. Recycling processes, while diverting waste from landfills, involve collection, sorting, and reprocessing, each with its own set of costs.

- Commodity Markets: The markets for recycled materials, like plastic, paper, and metal, are notoriously volatile. Fluctuations in demand and global market conditions can impact the profitability of recycling programs and even influence whether collected materials actually get recycled or end up landfilled. For instance, fluctuations in recycled PET (polyethylene terephthalate, used in plastic bottles) pricing can significantly affect the viability of municipal recycling programs.

- Value of Compost: Compost generated from organic waste represents a valuable agricultural amendment, enriching soil health and reducing the need for synthetic fertilizers. However, developing robust markets for compost and establishing efficient collection systems can be challenging.

- Extended Producer Responsibility (EPR): EPR schemes hold producers responsible for the end-of-life management of their products. This can incentivize the design of more easily recyclable or compostable products and fund the necessary infrastructure for their proper handling.

- Deposit Return Schemes and Financial Incentives: These programs offer refunds for returning specific containers, like bottles and cans, encouraging higher recycling rates. Other financial incentives, such as tax breaks for using recycled content or penalties for landfilling, can also influence material choices.

Pros:

- Job Creation: Recycling can create more jobs than landfilling, offering economic opportunities in collection, sorting, and processing.

- Valuable Byproducts: Composting produces valuable agricultural products, contributing to a more sustainable and resilient food system.

- Circular Economy Cost Savings: Circular business models, which prioritize reuse and regeneration, can reduce costs over traditional linear approaches that rely on resource extraction and disposal.

Cons:

- Volatile Recycling Markets: Recyclable material markets are volatile and often unprofitable, making it challenging to sustain recycling programs without government support or other incentives.

- Higher Upfront Costs: Compostable materials typically cost more to produce than conventional alternatives, potentially creating a barrier to wider adoption.

- Externalized Costs: Environmental externalities, such as pollution and resource depletion, are not fully incorporated into the pricing of conventional materials, creating a distorted market that doesn't reflect the true cost of these materials.

Examples:

- Fluctuating PET Pricing: As mentioned above, the fluctuating market value of recycled PET can significantly impact the financial viability of municipal recycling programs.

- TerraCycle's Brand-Sponsored Recycling: TerraCycle partners with brands to create recycling programs for materials not typically accepted in curbside recycling, demonstrating innovative approaches to extended producer responsibility.

- Vermont's Universal Recycling Law: This law, banning the landfilling of designated recyclables and food scraps, demonstrates a policy-driven approach to promoting sustainable materials management and has demonstrable economic impacts, both positive and negative, which are being studied.

Tips for Navigating the Economic Landscape of Compostable vs Recyclable:

- Total Cost of Ownership: Consider the total cost of ownership, not just the initial purchase price. Factor in end-of-life management costs, potential savings from using compost, and the long-term environmental benefits.

- Evaluate Long-Term Savings: Assess whether higher upfront costs for sustainable options deliver long-term savings through reduced waste disposal fees, lower resource consumption, and potential revenue streams from compost sales.

- Closed-Loop Systems: Seek out business models that prioritize closed-loop systems, where materials are continually reused and regenerated, minimizing waste and maximizing resource efficiency.

Popularized By:

- Ellen MacArthur Foundation: This foundation champions the circular economy framework, which promotes the elimination of waste and pollution, the circulation of products and materials, and the regeneration of nature.

- Tom Szaky (TerraCycle Founder): Szaky's work with TerraCycle demonstrates innovative approaches to recycling and resource recovery.

- Kate Raworth (Doughnut Economics): Raworth's Doughnut Economics model emphasizes the need for economic activity to operate within the ecological ceiling and social foundation, highlighting the interconnectedness of economic and environmental well-being.

Choosing between compostable and recyclable options requires a holistic understanding of the economic factors at play. By considering the entire lifecycle cost, supporting innovative business models, and advocating for policies that promote sustainable practices, we can create a more circular and resilient economy. This informed approach is crucial for individuals, businesses, and communities seeking to make environmentally responsible choices.

6-Factor Compostable vs Recyclable Comparison

| Concept | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Material Decomposition Process | Moderate - requires specific conditions | Medium - industrial facilities for compost | Nutrient-rich soil (compost), material reuse (recycling) | Waste disposal with facility access | Soil amendment; raw material conservation |

| Environmental Impact Analysis | High - comprehensive lifecycle assessment | High - data and expertise intensive | Quantified environmental footprints and impact comparisons | Policy-making, sustainability evaluations | Informs best environmental practices |

| Certification Standards | Moderate - multiple standard frameworks | Medium - testing and compliance efforts | Verified claims on compostability and recyclability | Product labeling and consumer trust | Consistent performance baseline; reduces greenwashing |

| Materials Science Innovation | High - research and development intensive | High - advanced materials and scaling needs | Novel compostable/recyclable materials with enhanced properties | Development of sustainable packaging and materials | Improved end-of-life options; addresses system gaps |

| Infrastructure & Processing | High - high capital and operational demands | High - facilities, logistics, and tech | Efficient collection, sorting, processing of waste streams | Regional waste management systems | Economies of scale; higher recovery rates |

| Economic Models & Market Dynamics | Moderate - complex financial and market flows | Medium - depends on market and policy | Viable business models promoting circular economy | Economic planning, sustainability investment | Job creation; circular business incentives |

Making Informed Choices: Your Role in Sustainable Disposal

Understanding the nuances of "compostable vs recyclable" is key to minimizing your environmental impact. From the decomposition process and environmental impact analysis to the importance of certification standards and the evolving landscape of materials science, this article has explored the multifaceted world of sustainable disposal. We’ve also delved into the critical roles of infrastructure, processing systems, economic models, and market dynamics in shaping how we manage waste. The most crucial takeaway is this: conscious disposal decisions matter. By understanding these concepts, you're not just sorting your trash; you're actively participating in building a more sustainable future, reducing landfill waste, conserving resources, and minimizing pollution. Your choices directly influence the health of our planet and the well-being of future generations.

Remember, the ideal choice between compostable and recyclable often depends on your local infrastructure. Consult your local council’s guidelines to ensure your efforts align with available facilities and contribute effectively to the circular economy. Mastering the difference between compostable vs recyclable empowers you to make informed decisions that truly make a difference.

Looking for a convenient way to support sustainable packaging and reduce your environmental footprint? Discover Naked Pantry, a business committed to eco-friendly practices. Visit Naked Pantry to explore their range of sustainably packaged products and join the movement towards a zero-waste future.

Article created using Outrank